Equipment required

The blades are made from what is commonly referred to as fibre glass. This is

mixture of glass fibre (maybe this is obvious, eh?), which has great strength in

tension and compression, resin, which provides rigidity when set, and a

number of other chemicals. The various chemicals required are listed here

along with their use and any special precautions required.

The various tools required are also listed here. Ensure that you have all this

equipment before starting the manufacturing process. Fibre glass product

suppliers will typically stock all the materials and chemicals required.

Chemicals required

Resin

There are many different types of resin, each with different properties. To

keep the design relatively simple, only two types of resin have been used for

the blade manufacture:

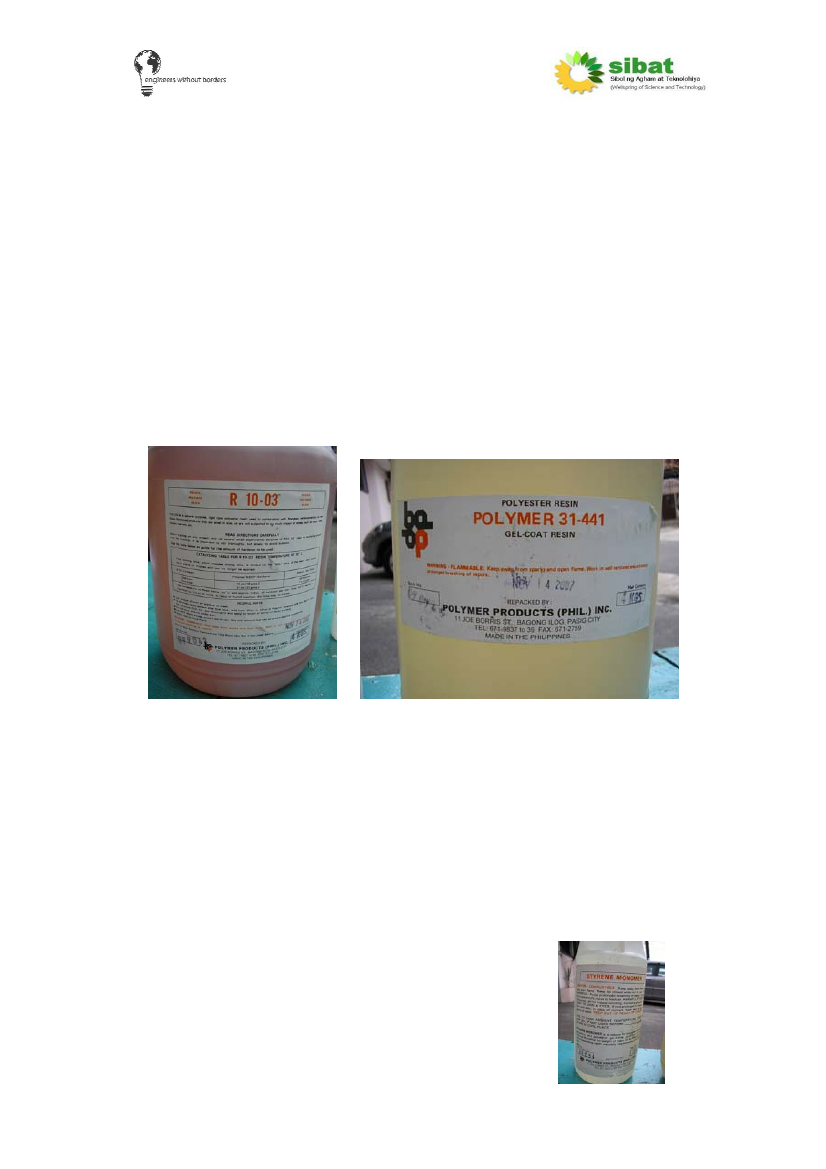

Resin Type ‘R 10-03’

This is a general purpose rigid orthopthalic (FRP) polyester resin. (Type ‘R 10-

03’ is a local manufacturer’s code number). It is relatively inexpensive and is

used for the majority of the wind turbine blades.

Resin Type ‘Polymer 31-441’

This is called a ‘gel coat’ polyester resin. (Again, type ‘Polymer 31-441’ is a

local manufacturer’s code number) It is 100% isophthalic with Neo-Pentyl

Glycol (NPG). It is very hard wearing and is scratch and chemical resistant. It

is more expensive than the other type of resin therefore its use is limited to

just the outer layers of the blade.

Styrene Monomer

This is mixed with the resin to reduce the viscosity of the

resin. This makes the resulting mixture more workable

and easier to ‘paint’ onto the fibre glass cloth.

6